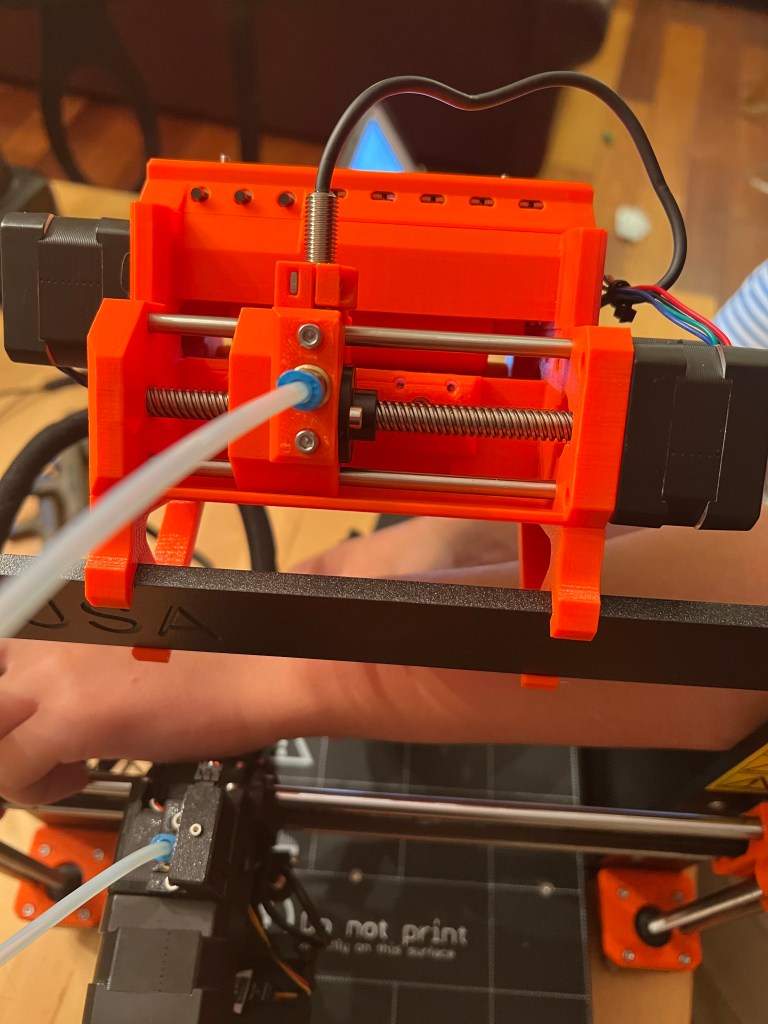

A DIY 3D Printed Rocket Launcher

After successfully launching a multitude of my 3D printed Bounty Towel rockets, my kids and I decided we needed a more badass rocket launcher than the bland and generic store bought mass manufactured versions. My biggest complaint with the generic store bought models is when you press the switch you get very little feedback on what is happening. This is especially concerning when the rocket doesn’t immediately launch. There is also ample opportunity for improvement in the aesthetics department on these devices.

If we wanted an awesome rocket launcher we were going to have to print, build, wire, and assemble it ourselves!

Model Rocket Launcher Plans

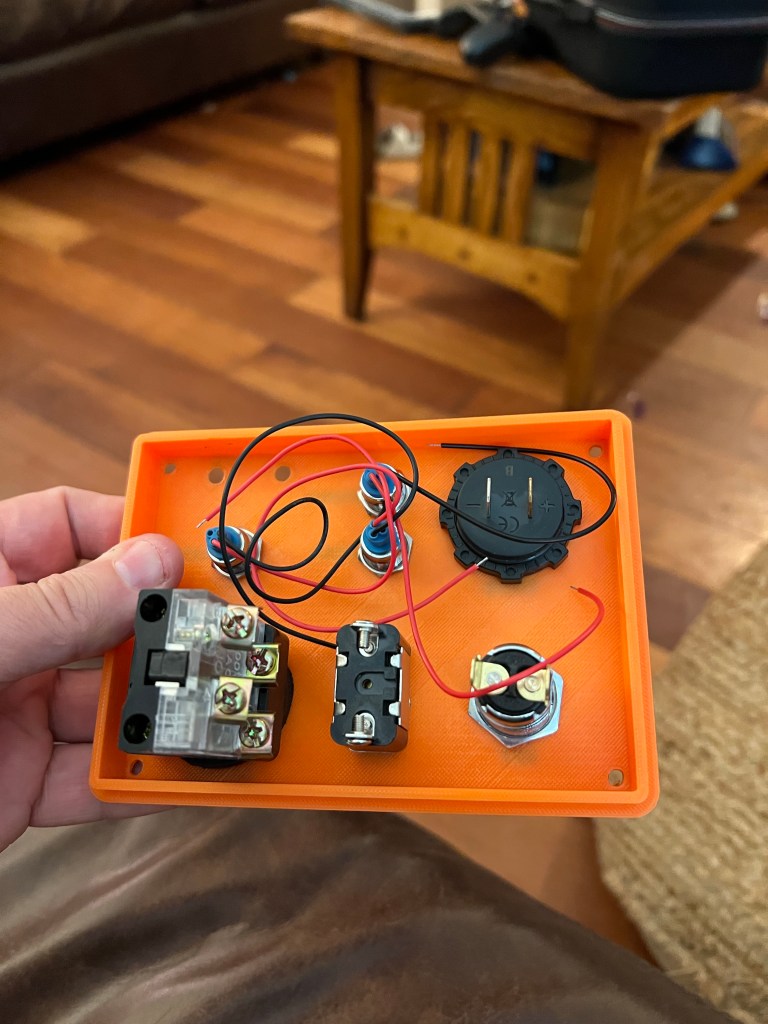

Bill of Materials (BOM)

- 3D Printed enclosure (cover + base are my design) <- Download here

- Battery Enclosure (8 AA Batteries)

- 12V Battery Voltage display

- 3 Indicator LEDs (for power, continuity and armed status)

- On/Off Key Switch

- 1 red cover toggle switch

- 1 red push button switch

- 4mm banana plug female terminals

- 3” Metal Handles (Qty 2)

- Optional Swag: Launch Key Lanyard

DIY MODEL ROCKET LAUNCHER CONTROLLER WIRING DIAGRAM